In a variety of medical and communications applications

wires of increasing smaller diameters required the removal of the insulating

jacket in order to expose the underlying metal conductor. These increasingly

small wire diameters make stripping using traditional methods such as

mechanical and chemical untenable. Furthermore in electronics, size reduction

of wires and increasing wire density in cables aligns well with laser wire

stripping. At the same time, wire stripping requirements are constantly getting

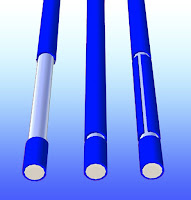

more challenging, with mid-span parts requiring selective removal (ie “window

pane” stripping).Thus the need for laser wire stripping as means of selectively

removing the wire insulation material.

The laser wire stripping process imparts no mechanical

force on the wire, which means delicate wires with diameters down to tens of

microns can be cleanly stripped. The material is typically removed by directing

a focused programmable beam (around 25μm in diameter) to the area requiring

laser wire stripping. This enables highly focused wire insulation removal, so

sections of wire insulation can be removed as needed. Changes to the size and

location of the removed sections can be made on the fly by calling up various

“cut” files with their associated profiles.In the laser wire ablation methods the material is removed in one of two ways. With the cut and peel method, a series of slices are made in the insulation are made that free the insulation from the wire. A post process manual or automatic method is employed in order to remove the cut insulation piece. This is process as part of laser wire stripping is typically done when the cycle time is critical and post-process material removal is acceptable. The ablation method removes all the material from the wire as the polymer insulation absorbs the light energy and is vaporized. The laser does not affect the wire beneath the insulation because the power levels needed to remove the insulation are much lower than those that would damage the metal wire. In addition the wavelength of the light energy, when it “hits” the metal is not absorbed in this type of laser wire stripping. This advantage can be augmented by selecting a laser wavelength that is readily absorbed by the polymers but not the wire.

Additional advantages of using lasers rather than chemical-based processes include safety benefits from eliminating chemical use, reduction of chemical handling and disposal costs, and support for a company's ISO 14001 sustainability program. Advantages over mechanical means include the lack of damage to the insulation in terms of indentations or stray pieces.

BEST’s laser wire stripping and

accurate length cuts will cost-effectively address all wire and cable

constructions including:

|

|